A sugar-containing polymer coating could one day help repair artificial joint implants, like hip replacements, when they are damaged through wear and tear, according to new research.

An international team of chemists and engineers, including Durham and York universities, UK, and Tsinghua University, China, has developed the technique for easily repairing low-friction surfaces.

Taking their inspiration from the way cartilage works to lubricate joints in humans, the team has found that rings of sugar can help a polymer latch on to surfaces and repair damage. It is hoped that the coating could also reduce friction-caused energy waste in mechanical systems, boosting efficiency. Eventually, they say that their discovery could extend the life-span of artificial joints, which are usually not repaired so easily – this can help with medical implants.

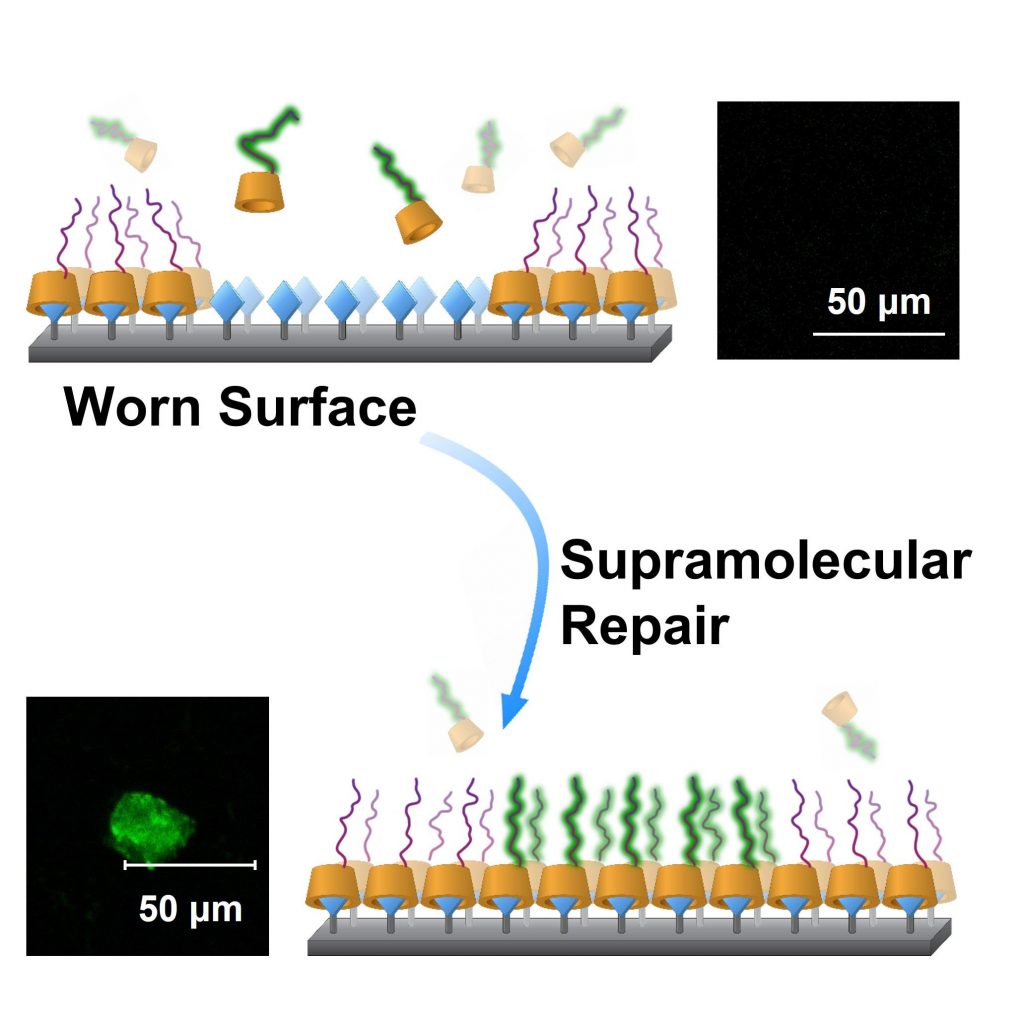

The research team found that if the polymer coating they have created is rubbed from a surface during use then a sugar ring in its structure allows it to reattach easily. This means that this coating then mimics the way cartilage works to lubricate human joints. Cartilage uses water to make a slick surface that minimises wear and tear. In the same way, the new coatings coax a layer of water to the surface, making it slippery and protecting the surfaces as they are knocked or rubbed.

Senior author Dr Paul McGonigal, Associate Professor in the Department of Chemistry, Durham University, UK, said: “Our sugar-containing coating gives us an appealing new way of patching up damage to low-friction surfaces.

“Hip and knee joints in our bodies stand up to decades of wear and tear thanks to the cartilage being repaired and replaced constantly. We have made materials that work in a similar way, but that are compatible with artificial joints.”

The polymer coating has two major parts: a long molecular chain with positive and negative charges to hold on to a water layer and a sugar ring is attached to one end of the chain. This ring anchors itself to a surface by docking with specific molecules, called adamantanes.

By treating titanium metal with these ring anchors, the researchers showed that the polymer coating becomes attracted to the surface. The weak, non-permanent links that form are key to the repair process.

Co-author Dr Yulong Sun, a researcher in Dr McGonigal’s laboratory at Durham University, spent time investigating the low-friction surfaces with PhD research student Yixin Wang and Prof Hongyu Zhang in Tsinghua University’s Department of Mechanical Engineering.

Dr Sun said: “Repair mechanisms are key to making materials that last a long time.

“Nature’s low-friction materials regenerate when they are damaged, but until now we haven’t had good repair mechanisms for artificial systems.”

Research co-author Dr Alyssa-Jennifer Avestro, a Dorothy Hodgkin Research Fellow at the University of York, said: “This is dynamic yet selective chemistry, which looks like it could be an effective way to undo the negative effects of mechanical wear on joints and other surfaces.

“If our protective coating layer is worn off, it is restored again without needing our intervention, thanks to targeted molecular recognition.”

The research was funded by the Engineering and Physical Sciences Research Council, the Royal Society, and Global Challenges Research Fund (all UK), the National Natural Science Foundation of China, National Key Research and Development Program of China, Precision Medicine Foundation, Tsinghua University, China, and Capital’s Funds for Health Improvement and Research, China.

Featured image: Dr Paul McGonigal & Chem with licence.